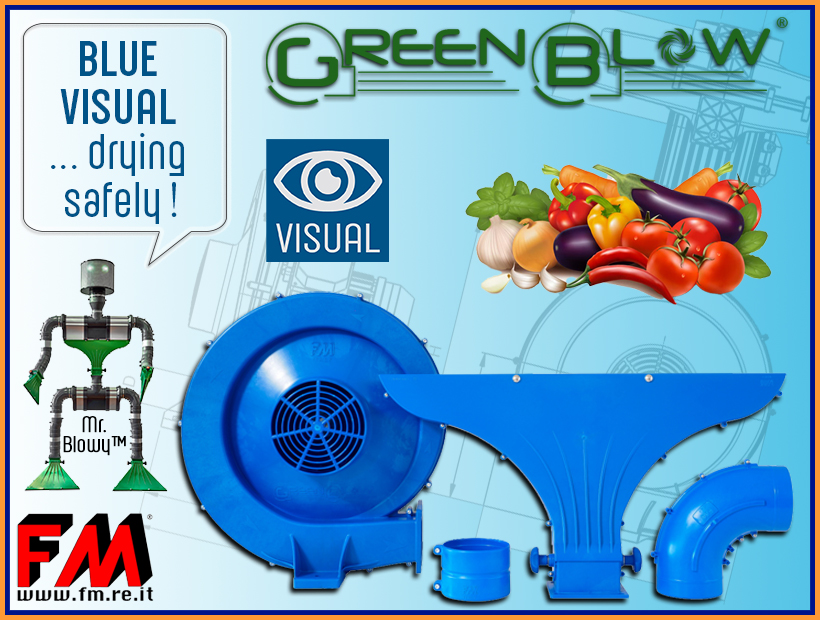

GreenBlow also becomes Blue Visual !

The application of the Green Blow Air Line in the Food sector, and 4th Range industry (fruit and veggies processing) , has forced us to design components that comply with high hygiene standards against accidental contamination in food preparations.

The application of the Green Blow Air Line in the Food sector, and 4th Range industry (fruit and veggies processing) , has forced us to design components that comply with high hygiene standards against accidental contamination in food preparations.

The same standards are also required in the pharmaceutical industry which has the same needs.

This is the main objective of the new Blue Visual version which significantly reduces the risk of accidental contamination by foreign bodies in environments where cleanliness, hygiene and safety are essential requirements.

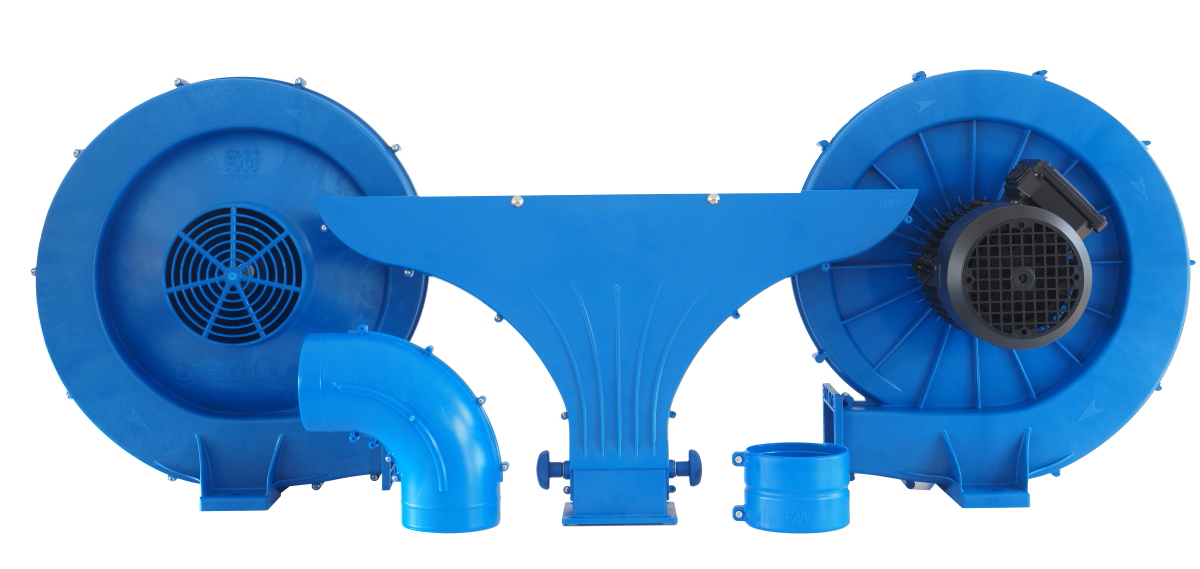

The Blue Visual line, compared to the standard one, is produced with technopolymers suitable for food contact, in Blue Color (RAL5005) and has all the screws and metal parts in stainless steel.

The blue material is widely used in the food industry as, due to its high visibility, it can be easily detected optically in line. Moreover, it is easier to determine the cleanliness of the components as spores, mold and residues of food and detergent are more visible on this color than on others.

The main features of the Blue Visual line:

The main features of the Blue Visual line:

- Corrosion and chemical resistance:

plastic materials which by definition do not present corrosion problems, and all the bolts and brackets made of stainless steel also guarantee chemical resistance (even if the use of strong bases and strong acids for cleaning is not recommended). The profiles used for the air knives are available on request in aluminum treated with hard anodizing for greater resistance;

- Resistance to temperatures: the technopolymers used are suitable for temperatures of around 70°C, while electric motors and inverters should not exceed 60°C and 50°C respectively.

These values refer to the temperature of the environment in which they are located. The treated product, on the other hand, can have much higher temperatures, the important thing is that there is no direct contact;

- Surface finishes and cleanability: the surfaces of all the components of the line have limited roughness so as to allow maximum cleanability even with simple water.