Smart Blow … tailor-made drying !

The Green Blow air line, recently, has met with great success in the Food & Beverage sector where the recurring problems mainly concern drying in the pre-labeling phase or in any case after steam sterilization processes.

The Green Blow air line, recently, has met with great success in the Food & Beverage sector where the recurring problems mainly concern drying in the pre-labeling phase or in any case after steam sterilization processes.

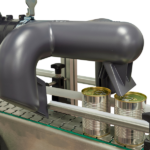

The growing applications made in this sector have led us to study a diffuser that could, in a small space, dry all the surfaces of the packaging.

In particular, one of the most difficult problems so far to solve was the drying of the upper part of the cans or the lower edge of the cap of the jars, in order to avoid the appearance of rust during storage in the warehouses.

Smart Blow, combined with the Green Blow Plus fan, eliminates this problem with a series of advantages.

SMART BLOW: a smart diffuser

Smart Blow is a highly customizable diffuser that brings together several advantages:

- Effective drying: in a single station there are 3 diffusers (one upper and two laterals)

which allow the drying of all the surfaces of the object;

which allow the drying of all the surfaces of the object; - Small dimensions: a single drying station need a space of only 600mm;

- Versatility: with the same diffuser it is possible to dry objects with similar dimensions without having to change the configuration at each change-over;

- Modularity: if the speed of the line does not allow perfect drying with a single station, it is possible to combine others in series, until the optimal result is obtained;

- Simple installation: it can be mounted on pre-existing lines. It does not need dedicated elements and no specialized technicians are needed;

- Low Costs: it is an economic alternative to all existing solutions, above all with limited energy consumption (indicatively from 1 to 2kW effective per station);

- Extremely low maintenance: the system does not require special maintenance if not replacing the filter, when necessary.

- Customizable: the shape of the final part of the 3 diffusers can be customized based on the shape of the packing to be dried, even with complex and particular shapes.