Customized Line

This line includes all customized items produced on customers’ demand.

The client is the owner of the equipment, which is also made by FM and is left on consignment in our mould warehouse:they are preserved after each production, to be used whenever the customer makes a restock.

The outlet branches of the Customer line are always sectors which need items with a high technical and technological contents: engineering (industrial automation), electronics, and automotive braking systems, alternative energies, agriculture, pneumatic equipment, components for interior design, construction, etc …

Right about this area, FM can put at the customer’s disposal its experience gained over many years of activity. We mention some specializations :

- WIDE KNOWLEDGE OF THE MARKET TECHNOPOLYMERS: thanks to the relationship with suppliers, research centers and universities, our market knowledge of polymers sweeps at 360°, in order to offer the best value-for-money based on the needs expressed by the customers. Besides, thanks to these partnerships, we can conceive new formulas of materials specifically for the application required.We are also able to provide specific compliant materials such as: UL, RoHS, REACH, FDA.

- METAL-REPLACEMENT: replacing metals with polymers after a proper structural and design assessment in order to optimize: lightness, strength, cost and shelf life of the end product. In addition, the metal-replacement speeds up, after a careful study, the assembly time with a significant cost reduction, improving the appearence and achieving a product with lower environmental impact (increased recycling and elimination of the use of paints for coloring).

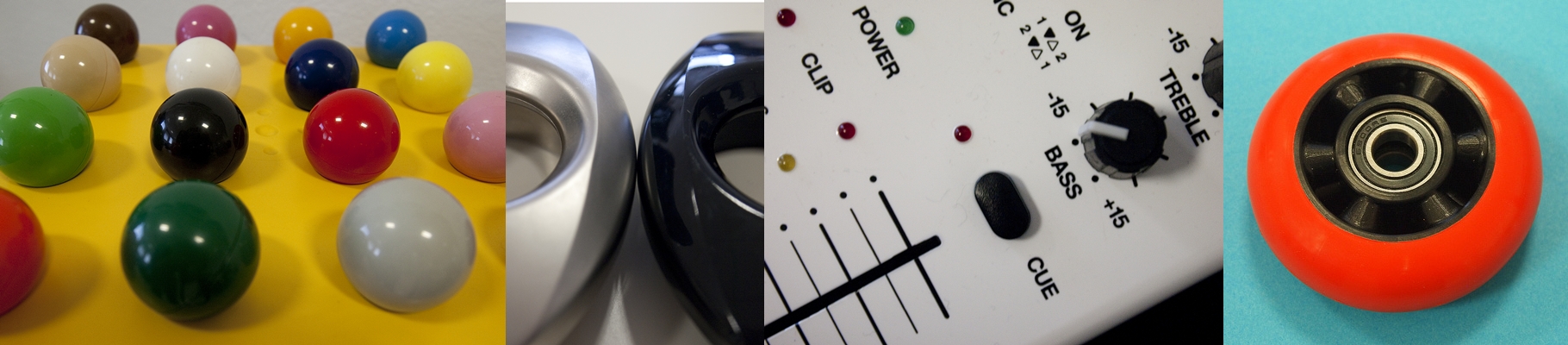

- BI-MATERIALS :Using two different plastic materials or co-moulded metal inserts, in order to take advantage of both metal characteristics (where necessary), together with polymer’s ones, to achieve the best end result.

- SERVICE WORK: thanks to an excellent network of sub-contractors and the internal assembly department, FM can also offer extra-moulding processes such as:

– Assembling: supply of semi-finished parts assembled with purchasing components and / or supplied in “work- on-account” (gaskets, screws, electronic cards, metal inserts, bearings, etc.

– Welding: ultrasonic or vibration

– Finishes (surface): galvanization, painting, embossing etc.

– Graphic details: pad and screen printing, foil stamping, etc..